Texels beer brewing process in eight steps

Curious about how Texels beer is brewed? This page takes you through the brewing process in eight steps. Would you like to see it with your own eyes? Then visit the brewery on Texel!

Step 1: Unmilled malt

The first step in the brewing process: the brewery cannot process barley and wheat grains directly from the land. They must first be malted in a malting plant. This process entails four steps: cleaning, soaking, germination and drying. To vary the taste, malt is roasted. Lightly-roasted types of malt are used for the blond beers, and more heavily-roasted types for the dark ones.

Step 2: Milled malt

The second step in the brewing process: at the start of the brewing day the malt is milled. Milling is the crushing of the grains of malt to release the starch while leaving the husks (the chaff) intact. This crushing is done in a grinder with two rollers between which the grains are crushed.

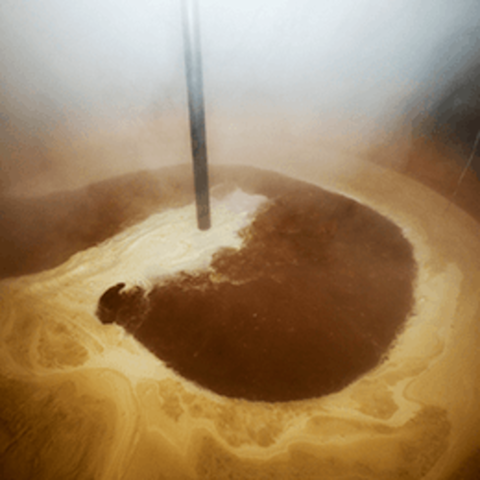

Step 3: Pouring the malt

The third step in the brewing process: when the water in the mash tun has reached the right temperature, the milled malt is poured into it. This ‘mash’ is then heated in steps to 75ºC (167ºF). During this process the starch is converted into several kinds of sugars. The fermentable sugars are converted into alcohol by the yeast cells, and the non-fermentable sugars remain as a ‘sweetener’ in the beer.

Step 4: Filtering the mash

The fourth step in the brewing process: the mash is filtered in the filtration tank. The husks of the malt grains (the chaff) form the filter bed. The sugary liquid in the mash sinks down through this bed and is collected. Then the filter bed is sprayed with fresh water to wash out all the sugar residues. This water is also collected.

Step 5: Beer in the making

The fifth step in the brewing process: all the liquid that has passed through the filter is collected in a container, and is then pumped to the brew kettle. This liquid is called ‘wort’. The amount of sugar in the wort determines the alcohol content of the final beer. That’s why the brewmaster checks the sugar concentration. The filtration is halted when the desired sugar concentration has been reached.

Step 6: Addition of high-grade hop varieties

The sixth step in the brewing process: there are various hop varieties, of which only the female hop is used. Each hop variety has its own character. Adding them in different proportions lets the brewers give each speciality beer its distinctive taste. The used hop flowers are compressed into pellets, large grains that are easy to mix.

Step 7: Adding hop varieties

The seventh step in the brewing process: the wort, which has been pumped to the brew kettle, is heated there again. The brewers add the various hop varieties during this heating.

Step 8: Boiling the wort

The eighth step in the brewing process: after adding the hops, the brew is brought to the boil. The hop aromas are released and dissolve in the beer during boiling. The heating also sterilises the beer.

You determine the final step

The beer is ready on tap and bottled. Prefer to taste it at our brewery, or with your loved ones in your own environment? The choice is yours!

Working at the Texelse Bierbrouwerij

Would you like to help build our wonderful brand? Then take a quick look to see whether working for Texels might suit you. We’d like to get in touch with you!